| |

|

|

.Top »

Products

» CD-G7 NC PCD Tool Grinding Machine |

|

|

|

CD-G7

NC PCD Tool Grinding Machine |

|

|

|

|

APPLICATION:

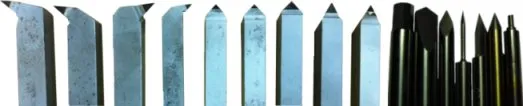

Lathe tool,

Disposable blade,

End mill, Dresser

,Cutting tools which are made by super head tool,

Cutting tools which are made by super hard

tool, polycrystalline diamond (PCD) and polycrystalline cubic boron

nitride (PCBN), Carbide, HSS (High Speed Steels)

etc..

FEATURES:

-

Servo control system

Friendly

operational interface. Users don't need to learn how to write

the program.

Fool-proof tutorial. Using the handwheel, joystick and the touch

screen, users can

operate the machine easily, including setting up the parameters

of the system

(system locations, speeds, turning directions).

-

Operational interface

We

provide multilingual options. Users can switch between languages

easily and

quickly. There is also a built-in database, users can save all the

parameters of the tools

(including the distance and speed of traversing) in the data base.

Saving and loading

processes are very quick and easy.

-

Standard T-shaped tool stand

We provide several

kinds of quick clamping holder which are

all very easy to loosen up and change. It can also be

custom-made according to the specifications of

special tools. Users can use the handle at the back

to quickly lock the tool stand. Release the handle at

the bottom, then users can quickly move or change

the whole stand.

-

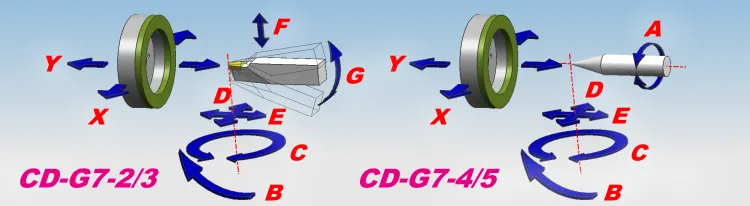

Adjust tool stand (Optional accessories)

F-axis up/down 30mm

and users can adjust the G-axis inclination

from 10° to 20°. With the machine's B-axis inclination (between 0°

to

25°), it would be able to grind tools with large clearance angle.

-

Manual A-axis Rotational tool stand (Optional accessories)

It supports all

kinds of tools, including end mill, engraving bits...

-

Wheel flange with extractor

Users can take down the flange directly and change for a different wheel. There is no need

to repeatedly dress to keep the wheel face level.

-

CCD Video scope system

The microscope has multi-time

magnifications. With the high sensitivity CCD camera and big

screen, users can easily observe small tools. During grinding,

users can constantly monitor the tools and measure the radius of

the tool. The microscope system is sealed and protected and it

has safety lense to stop grind dust and coolant from getting in,

so it is more durable.

|

|

CD-G7

NC

PCD Tool Grinding Machine

SPECIFICATIONS |

|

Model |

CD-G7-2 |

CD-G7-3 |

CD-G7-4 |

CD-G7-5 |

Wheel head |

Spindle driver motor |

2P 2.2 Kw (3HP) |

Spindle speed (60Hz) |

100 ~ 3,600 rpm (Program controlled) |

X-axis traverse |

300mm(Servo system, Divisions of 0.0001mm) |

Y-axis infeed |

50mm(Servo system, Divisions of 0.0001mm) |

|

Wheel flange |

Wheel flange with extractor |

Tool stand |

D-axis movement |

40mm (Manual) |

E-axis movement |

45mm (Manual) |

F-axis up/down |

30mm(Adjust tool stand, Optional) |

-------- |

|

G-axis inclination |

-10°~20°(Adjust tool stand, Optional) |

Worktable |

B-axis inclination |

0°~25°

(Manual) |

0°~25°

(Program controlled) |

C-axis pivot angle |

-120~120°

(Manual, Divisions of 0.05°) |

-120~120°

(Servo system, Divisions of 0.001°) |

C-axis clamp |

Manual |

Program controlled |

|

A-axis Rotational |

-------- |

(360°,Servo

system) |

|

Vision system |

CCD Video scope system |

|

Touch screen (HMI) |

7" |

10" |

|

Coolant system |

1/8Hp standard coolant system |

|

Wheel dimensions |

150ø

× 40H

×

40T |

STANDARD ACCESSORIES

-

Spindle with variable speeds

-

CCD Video scope system -

Wheel flange with

extractor

-

Standard T-shaped tool stand

-

Standard coolant system

-

Work lamp

-

Tool box with tools

|

OPTIONAL ACCESSORIES

|

|

Our company reserved the rights to change the design and standard equipments. |

|

|