| |

|

|

.Top »

Products

» CD-358P PCD Tool Grinding Machine |

|

|

|

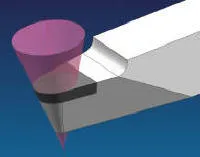

CD-358P

PCD Tool Grinding Machine |

|

In recent years, our

industry has been changing. Cutting tools which are made by superhard

tool, polycrystalline diamond (PCD) and polycrystalline cubic boron

nitride (PCBN) etc.. have replaced the traditional ones and have being

dominating the market for a while now. Because PCD or PCBN tool

regrinding presents certain difficulties and requirements,

conventional Grinding Machine can't keep up with them; therefore, they

have to be sent back to the original factories to do the tool

regrinding. This process not only wastes your precious time, but also

your money. To solve this dilemma, we had put lots of effort and time

into developing this CD-358P PCD & PCBN tool Grinding Machine, and we

believe that it can help your company to save on the costs.

|

|

|

APPLICATION:

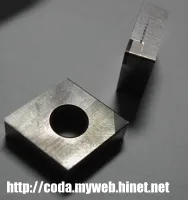

Lathe tool,

Disposable blade,

End mill, Dresser ,Cutting

tools which are made by super head tool,

Cutting tools which are made by super hard tool, polycrystalline diamond (PCD)

and polycrystalline cubic boron nitride (PCBN),

Carbide, HSS (High Speed Steels)

etc..

FEATURES:

-

Standard T-shaped tool stand

We provide several kinds of quick

clamping holder which are all very easy to loosen up and change. It

can also be custom-made according to the specifications of special

tools. Users can use the handle at the back to quickly lock the tool

stand. Release the handle at

the bottom, then users can quickly move or change the whole stand.

-

CCD Video scope system

The microscope has 10-time magnifications. With

the high sensitivity CCD camera and big LCD screen, users can

easily observe small tools. During grinding, users can constantly

monitor the tools and measure the radius of the tool. The

microscope system is sealed and protected and it has safety lense

to stop grind dust and coolant from getting in, so it is more

durable.

|

|

CD-358P

PCD Tool Grinding Machine

SPECIFICATIONS |

|

Model |

CD-358P |

CD-3562P |

|

Spindle driver motor |

2P 2.2 Kw (3HP) |

Spindle speed (variable) |

100~3,600 rpm |

|

Swivel

angle (B) |

-5°~20° |

High adjustment (Z) |

115mm |

|

Oscillation stroke (X1,

variable)

|

0~10mm |

|

Oscillation stroke

(variable) |

0~60 strokes/min. |

|

Transverse travel

(X2,

variable)

|

300 mm |

|

Tool stand |

Longitudinal (D) |

150 mm |

Cross

travel (E) |

50 mm |

|

Worktable size |

158×210 mm |

Pivot angle (C) |

-120~120°

Encoder (Divisions of 0.05°) |

|

Infeed (Y) |

90mm, Manual |

90mm, Servo system |

|

Infeed

line scale

accuracy |

0.005mm, Line scale |

0.001mm, Servo

system |

|

Touch screen (HMI) |

-------- |

7'' |

|

Vision system |

TV, CCD Video scope system |

|

Coolant system |

Standard coolant system |

|

Measurement (LxWxH) |

(without

Coolant System) |

|

Machine

weight |

1680 Kg |

|

Wheel dimensions |

150ø

×

40H

× 40T |

STANDARD ACCESSORIES

|

OPTIONAL ACCESSORIES

|

|

Our company reserved the rights to change the design and standard equipments. |

|

|